AI Inventory Management Software: A Beginner’s Guide to Smarter Stock Control

Think of AI inventory management software as a super-smart assistant for your business. Instead of you manually poring over spreadsheets and making educated guesses, this software uses artificial intelligence to predict what your customers will buy and when. It then automates ordering to make sure you have the right stuff on your shelves at the right time. It's all about switching from gut feelings to data-driven decisions, helping you avoid both the pain of "out of stock" signs and the cost of a warehouse full of products nobody wants.

What Is AI Inventory Management Software?

Imagine trying to manage your store's inventory with just a clipboard. You're constantly trying to track what's selling, guess what might be a hot item next season, and just hope you don’t run out of a bestseller during a surprise sales rush. That old-school approach is reactive, stressful, and full of expensive uncertainty.

Now, let's flip the script.

What if, instead of just looking at past sales, you had a system that was more like a crystal ball for your business? It doesn't just see what you sold last month; it analyzes current market trends, knows an upcoming holiday will boost certain products, and can even predict how a local festival might affect demand. This is the magic of AI inventory management software. It shifts your entire operation from a reactive guessing game to a proactive, data-backed strategy.

Here’s a simple way to think about it: traditional inventory is like writing a grocery list from memory and hoping you didn't forget the milk. An AI-powered system is like a smart fridge that knows your family’s habits, sees you're running low, and automatically adds milk to your shopping list before you run out.

It's More Than Just Automation

It's easy to think of this as just a fancy spreadsheet, but that's not the whole story. While basic inventory software can tell you what you have in stock, an AI system actually learns and adapts over time. It’s built to handle the sheer complexity and speed of modern business.

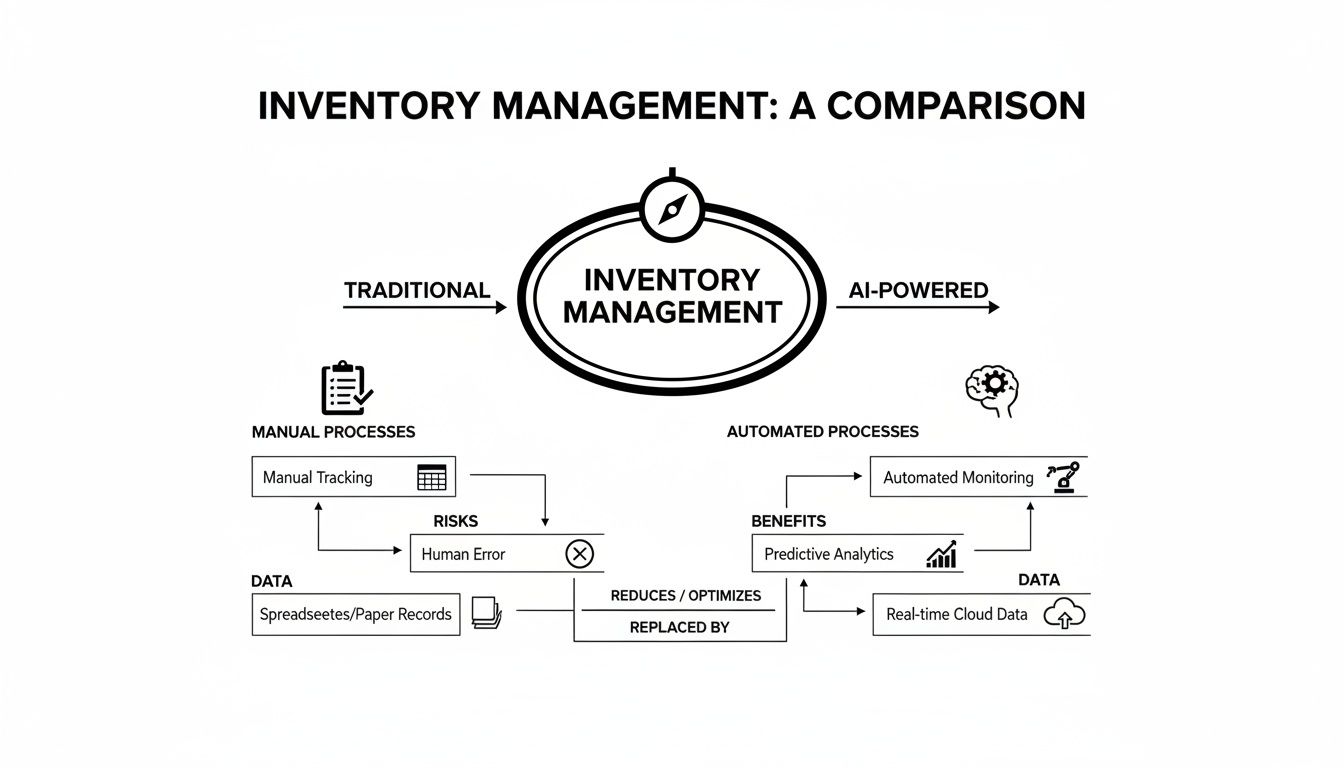

Here’s a quick comparison to show you what I mean.

Traditional vs AI-Powered Inventory Management

This table breaks down the practical differences between old-school inventory methods and what a modern AI solution can do for a small business.

| Aspect | Traditional Method (Manual) | AI-Powered Method (Automated) |

|---|---|---|

| Forecasting | Based on historical sales and gut feelings. | Uses machine learning to analyze trends, seasonality, and external factors. |

| Reordering | Fixed reorder points (e.g., "order when stock hits 20 units"). | Dynamic reorder points that adjust based on real-time demand shifts. |

| Error Handling | Relies on manual audits to find discrepancies. | Automatically flags anomalies like sudden sales dips or data entry errors. |

| Decision-Making | Reactive; responds to stockouts or overstock after they happen. | Proactive; anticipates demand to prevent issues before they occur. |

| Efficiency | Labor-intensive and prone to human error. | Automates routine tasks, freeing up staff for strategic work. |

As you can see, the jump from traditional to AI-powered systems isn't just an upgrade—it's a fundamental change in how you manage a core part of your business.

So, what really sets these AI systems apart?

- Dynamic Adjustments: An AI doesn't rely on static, "set-it-and-forget-it" rules. It constantly revisits its forecasts as new data comes in, making sure you're always aligned with what customers are actually doing.

- Pattern Recognition: The software can spot subtle patterns a human would almost certainly miss—like a tiny but consistent increase in sales for a specific item that signals it's about to become a major trend.

- Data-Driven Decisions: Every recommendation, from placing a purchase order to suggesting a product for clearance, is backed by cold, hard data. This pulls human bias and emotion out of what should be purely business decisions.

Expert Opinion: "AI doesn't just automate tasks; it elevates decision-making. We've seen it transform inventory from a simple cost center into a strategic asset that can directly boost revenue and customer satisfaction."

Of course, this level of intelligence is completely dependent on good data. To get accurate predictions, your AI needs clean, well-organized information to work with. For any business heading down this path, getting a handle on data management is step one. You can learn more about this by exploring fundamental data governance best practices to get your organization ready. Think of it as putting the right fuel in the engine before you start the race.

How AI Transforms Your Inventory Management

At its core, AI inventory management software isn't about some impossibly complex algorithm; it’s about swapping guesswork for informed decisions. Instead of just reacting to what happened last week, these systems help you get ahead of what’s coming next. This fundamental shift from reactive to proactive management is driven by a few key capabilities that work together to make your business smarter, faster, and more profitable.

Let's pull back the curtain and look at the three main ways AI makes this happen.

Predictive Demand Forecasting

Think of traditional forecasting like driving while looking only in the rearview mirror. You're basing all your future decisions on past sales data. But what if you sell umbrellas and it’s about to rain for a week straight? Historical data alone won’t prepare you for that sudden spike in demand.

AI-powered predictive forecasting, on the other hand, is like having a sophisticated weather app, a real-time traffic GPS, and an economic advisor all feeding you insights. It doesn't just look at your past sales; it analyzes a massive range of external factors—market trends, competitor pricing, social media buzz, weather patterns, and even shipping lane disruptions.

This diagram shows just how different the two approaches are.

You can see the clear contrast between the manual, often error-prone nature of old-school inventory control and the data-driven precision of an AI system.

Here’s a practical example:

Imagine you run an online coffee subscription box. A traditional system sees you sold 500 boxes last November and tells you to order for that amount. An AI system sees that, but it also notes a popular influencer just mentioned your brand, a new competitor launched, and a major shipping carrier announced holiday delays. It puts all this together to predict you'll actually need 650 boxes and should order your packaging supplies two weeks earlier than usual.

Automated Replenishment

Once you have a solid forecast, the next logical step is acting on it. Manually creating purchase orders is a grind, and it's dangerously easy for human error to creep in. A misplaced decimal or a forgotten zero can mean ordering 10 items instead of 100, or 1,000 instead of 100. Automated replenishment takes this critical—but repetitive—task off your plate, acting like a tireless and perfectly accurate purchasing agent.

The system doesn’t just reorder when stock hits a static number. It dynamically adjusts reorder points based on the new demand forecast, current supplier lead times, and your own real-time sales velocity.

Expert Opinion: "The goal isn't just to automate ordering; it's to create an intelligent flow of goods. The system ensures that inventory arrives precisely when it's needed, minimizing carrying costs without ever risking a stockout. It’s about being lean, not cheap."

This means the AI is constantly working to keep your inventory levels lean but effective. It frees up cash that would otherwise be tied up in excess stock sitting on a shelf. In fact, studies have shown that AI can help businesses reduce excess inventory by up to 30%—a huge saving for any company.

Dynamic Stock Optimization

Let's be honest: not all products are created equal. Some fly off the shelves, while others just gather dust, tying up valuable capital and warehouse space. Dynamic stock optimization is basically your AI’s financial strategy function, constantly analyzing your product catalog to squeeze the most profit out of every item.

The software is brilliant at identifying these slow-moving products—often called "dead stock"—and can suggest concrete actions to deal with them.

- Suggesting Promotions: It might flag a product whose sales have slowed over the past 90 days and recommend a "buy one, get one" deal to clear it out.

- Recommending Bundles: The AI could identify that customers who buy your best-selling product often look at a slower-moving accessory, then suggest you create a discounted bundle to move both.

- Advising Discontinuation: For products that consistently underperform even with promotions, the system provides the cold, hard data needed to make the tough decision to cut them loose and reallocate that capital to proven winners.

This continuous analysis ensures your inventory investment is always working as hard as possible for your bottom line. It’s all about making sure every single dollar you spend on stock generates the highest possible return.

Seeing AI Inventory Software in Action

Alright, let's move beyond the buzzwords. It's one thing to talk about predictive forecasting, but it’s another thing entirely to see how these tools actually help a real business. This is where theory meets the balance sheet.

Let’s look at a few practical examples that show how AI inventory management software is changing the game across different industries.

These aren't just stories; they're blueprints for shifting from reactive "firefighting" to proactive, strategic planning.

The Fashion Retailer That Cut Waste and Boosted Profits

Picture a clothing boutique gearing up for the spring collection. The old way involved digging through last year's sales reports and making an educated guess—a bit of art, a bit of science—on how many blue dresses and khaki shorts to order. More often than not, this led to a messy clearance rack full of unpopular sizes and colors, representing thousands in lost profit.

Now, they use an AI system. This software goes way beyond their own sales history. It scans social media trends, digests runway reports from fashion week, and even factors in regional weather forecasts.

How the AI Made a Difference:

- It predicted that "terracotta" would be a breakout color, but pinpointed that its popularity would be concentrated in cooler, northern climates.

- It also saw a growing demand for medium and large sizes based on shifting customer demographics in their key markets.

- Armed with these insights, the store adjusted its orders, stocking up on terracotta jackets for one region and breezy linen shirts for another.

The result? They saw a 25% reduction in end-of-season markdowns. That's not a lucky guess; it's a calculated business decision that freed up cash and dramatically cut down on waste.

The E-commerce Store That Nailed Its Holiday Sales

Next up, an e-commerce business running three warehouses across the country. Their biggest headache was always the Black Friday rush. They were constantly struggling with having too much stock in one location and not enough in another. Worse, they’d sometimes oversell a hot item and have to cancel orders, leaving a trail of frustrated customers.

Their new AI inventory platform acts like an air traffic controller for their products. It doesn't just track what they have; it optimizes where it should be.

Expert Opinion: "For e-commerce, AI isn't just about having inventory. It's about having it in the right place to meet shipping promises. A happy customer is one who gets their order on time, especially during the holidays."

During the sale, the AI dynamically reallocates inventory based on where the orders are coming from in real-time. If the East Coast warehouse is running low on a popular gadget, the system instantly starts routing new orders to the Midwest location—no human intervention needed. This allowed them to keep their two-day shipping promise, even at peak volume.

They managed to avoid overselling completely and saw their customer satisfaction scores jump by 15% after the holiday season.

The Manufacturer That Eliminated Production Delays

Finally, let's look at a small company that builds custom furniture. Their absolute worst-case scenario is the entire production line grinding to a halt because they ran out of a specific hinge or a certain type of wood. A stockout on a single, inexpensive component could easily delay a $10,000 order.

Today, they rely on an AI system to manage their raw materials. The software syncs with their production schedule and sales pipeline, analyzing the materials needed for every confirmed and pending order. It even accounts for supplier lead times and potential shipping delays.

Here’s a practical example: If the AI flags a potential delay on an incoming shipment of oak, it immediately alerts the purchasing manager and suggests an alternative, pre-vetted supplier. This proactive risk management keeps the production line humming, preventing costly downtime and maintaining trust with their clients.

These examples make it clear that AI is fundamentally changing how businesses handle their stock. In retail alone, the global AI inventory management market is valued at around $6.7 billion and is projected to explode to $33.6 billion by 2034. You can dig deeper into these numbers with forecasts from InsightAceAnalytic.

A Practical Guide to Adopting AI Inventory Software

So, you're ready to make the switch to a smarter system? Excellent. Moving to AI inventory management software doesn't have to be a technical headache. The best way to think about it is as a four-stage journey—from research to full launch—where each step sets you up for success in the next.

This guide is your roadmap. It's designed to get you from point A to point B without the stress and confusion that often comes with new tech projects. Let's walk through it.

Choosing the Right Partner

The first—and arguably most critical—step is picking the right vendor. Let's be clear: not all AI platforms are created equal. The powerhouse system built for a massive corporation will likely be total overkill for your growing e-commerce store. You need a partner whose technology and support actually fit your business.

When you start talking to potential vendors, push past the feature list. You need to ask about outcomes. "How, specifically, will your system help me reduce stockouts?" or "What kind of impact can I expect on my carrying costs?" A good partner will have confident, straight answers for you.

To help guide those conversations, here's a checklist of questions you should be asking.

Vendor Evaluation Checklist

Choosing a vendor is a major decision. Use this table to make sure you're asking the right questions and understanding why they're so important for your business's future.

| Question Category | Key Questions to Ask | Why It Matters |

|---|---|---|

| Integration | "How does your software connect with our current systems, like Shopify or our POS?" | Seamless integration is non-negotiable. It stops you from having to do manual data entry and ensures the AI has a real-time, accurate picture of your operations. |

| Scalability | "Can your system grow with us as we add more products or sales channels?" | You need a solution that can keep up with your ambition. The last thing you want is a tool that holds you back as you expand. |

| Support | "What does your onboarding and customer support process look like?" | Don't underestimate this. A strong, responsive support team is absolutely vital for a smooth rollout and getting the most out of the system long-term. |

| Proof | "Can you share case studies or connect us with a similar business using your software?" | Real-world examples are everything. They prove the software's effectiveness and help you set realistic expectations for what you can achieve. |

Getting clear answers here will help you separate the true partners from the mere software sellers.

Preparing Your Data

Once you’ve found a promising partner, the focus shifts inward to your data. Think of your historical sales data as the fuel for your new AI engine. You wouldn't put dirty, low-quality fuel into a high-performance car and expect it to run well, right? The exact same principle applies here.

The AI learns from your past performance to predict future trends. If your data is messy, incomplete, or just plain wrong, the forecasts it produces will be just as flawed. This "garbage in, garbage out" problem is one of the single biggest reasons these implementation projects fail to deliver.

Expert Opinion: "The success of any AI inventory system is fundamentally tied to the quality of the data it's fed. Clean, accurate historical data is non-negotiable—it’s the foundation upon which all predictive insights are built."

Roll up your sleeves and get to work. Focus on cleaning up your sales history, making sure product SKUs are consistent across all systems, and verifying your supplier lead times. It might feel like grunt work, but this upfront effort will pay off massively down the line.

Seamless Integration

With clean data ready to go, it's time to connect everything. This integration phase is where your new AI software plugs into the other tools that run your business. The goal is to create a central nervous system for your operations, where information flows freely and automatically between platforms.

For this to work, your AI software needs to talk to a few key systems:

- Your Point-of-Sale (POS) System: This gives the AI instant visibility into every single in-store sale as it happens.

- Your E-commerce Platform (e.g., Shopify, BigCommerce): This is crucial for feeding the AI real-time data on online orders, returns, and even customer behavior.

- Your Warehouse Management System (WMS): This syncs the physical stock levels on your shelves with the AI’s digital records, ensuring they always match.

A good vendor will do most of the heavy lifting here, but your team's involvement is crucial to double-check that everything is connected properly. For a deeper dive into the high-level strategy behind a project like this, our comprehensive AI implementation roadmap is a great resource.

Team Training and Onboarding

The final piece of the puzzle is your people. You could have the most powerful software on the planet, but it's not going to do much good if nobody knows how to use it confidently.

Effective training isn't just about showing people which buttons to click. It’s about building their trust in the new system.

Start by explaining the "why" behind the change. Show your team how this new AI tool will eliminate tedious tasks like manual purchase orders and free them up to focus on more valuable work, like improving customer service or launching new marketing campaigns. Get them excited. Once they see it as a tool to make their jobs easier, adoption will be a breeze. Most vendors offer solid training programs, so make sure you take full advantage of them.

Navigating Common Implementation Challenges

Let's be realistic—adopting any powerful new technology has its bumps, and bringing AI inventory management software into your business is no exception. While the payoff is massive, a few common hurdles can trip people up. Knowing what they are ahead of time is the best way to ensure a smooth rollout.

Interestingly, these challenges are rarely about the tech itself. They're about data, people, and expectations. By getting in front of them, you can map out a much smoother path to success.

The Garbage In, Garbage Out Problem

There's an old saying in data science that couldn't be more true here: "Garbage In, Garbage Out." Your AI system is only as smart as the data you feed it. If your sales history, supplier info, and product details are a mess, the AI's forecasts will be just as unreliable. It’s like trying to navigate a new city with a map that’s missing half the streets.

Before you even think about flipping the switch on your new software, you have to prioritize data hygiene. This isn't a one-and-done cleanup; it’s about creating better habits for the long haul.

- Audit Your Data: Get your hands dirty and dig into your current records. Are your product SKUs the same across all sales channels? Are your supplier lead times actually correct?

- Standardize Inputs: Set up clear, simple rules for how data gets entered from now on. This stops bad data at the source.

- Clean As You Go: Make it a regular practice to review and fix data. A little proactive work prevents tiny errors from snowballing into huge forecasting headaches.

Overcoming Resistance to Change

The next roadblock has almost nothing to do with software and everything to do with people. Your team has a rhythm, a way of doing things they've relied on for years. When you introduce a tool that automates tasks they used to own, it's natural for them to feel skeptical or even threatened. The question, "Is this thing going to take my job?" is a very real and valid concern.

The only way through this is with transparent communication. You have to frame the AI as a helpful assistant, not a replacement.

Expert Opinion: "The goal is to show your team how the AI makes their jobs better, not obsolete. When they see it as a tool that eliminates tedious spreadsheet work and lets them focus on more strategic tasks, they become champions of the change."

Show your team how the AI inventory management software can save them from spending hours buried in spreadsheets. This frees them up for higher-value work, like building supplier relationships or analyzing new market opportunities. Get them involved in the training early, and genuinely listen to their feedback.

Managing Realistic Expectations

Finally, it's critical to set the right expectations. AI is an incredibly powerful tool, but it isn't a magic wand. It won't fix every inventory issue on day one. The system needs time to digest your data and calibrate its algorithms to your specific business.

The first few forecasts might be a bit off. That's normal. The AI makes a prediction, compares it to what actually happened, learns from the difference, and makes a better prediction the next time. This constant learning loop is where the real magic happens.

Think of it like hiring a brilliant new employee. They won't know every quirk of your business on their first day, but with time, they'll learn the ropes and become indispensable. Your AI needs a few sales cycles to truly get the hang of your unique demand patterns. To get a full picture of the investment, check out our guide on the cost of implementing AI. A little patience in the first few months will pay off tenfold with sharp, valuable insights down the line.

The Future of Smart Inventory Control

So, where is all this heading? The evolution of AI inventory management software isn't just about fine-tuning the tools we have today. We're on the brink of creating truly autonomous, interconnected supply chains that practically think for themselves. Jumping in now doesn't just fix current headaches; it sets your business up to win in the long run.

Today's AI is already a game-changer, but the trends on the horizon are even more exciting. We're moving away from simply predicting what will happen and toward building a proactive, self-driving operation.

Hyper-Automation and Connected Ecosystems

One of the most exciting developments is the move toward hyper-automation. Picture this: an AI that doesn't just ping you with a reorder suggestion—it handles the entire thing on its own.

- The moment inventory levels approach a dynamically calculated threshold, the AI automatically sends a purchase order to your supplier's system.

- It then communicates with your logistics partner to book the shipment.

- Finally, it gives your warehouse team a heads-up with a precise arrival time.

This creates a seamless, machine-to-machine workflow. Routine tasks get done in an instant, without a single human touch, all while the AI is constantly optimizing for the best cost and fastest delivery.

The Rise of IoT Integration

Another huge leap forward is deeper integration with the Internet of Things (IoT). Think tiny, inexpensive sensors on pallets, boxes, or even individual high-value products, all feeding a constant stream of location and condition data.

Your AI system won't just assume you have 100 units in stock. It will know the exact location of all 100 of them, whether they're on the factory floor, in a delivery truck, or sitting on a shelf. This level of detail practically eliminates stock-outs and gives you incredible control over your entire supply chain.

Expert Opinion: "What was once a high-cost tool for massive corporations is rapidly becoming an accessible and essential asset for small and medium-sized businesses. The barrier to entry is falling, but the competitive advantage it offers is only growing."

This isn't just a fleeting trend; it's a fundamental shift in how business will be done. The market numbers tell the same story. The AI in inventory management market was valued at around USD 11.8 billion in 2025, but it's projected to explode to USD 84.7 billion by 2034. This growth shows just how much companies are coming to rely on smart automation. You can dig deeper into this market expansion in a comprehensive outlook from ResearchAndMarkets.

Adopting intelligent inventory control today isn't just another upgrade. It’s about getting your business ready to compete and thrive in a much more automated and intelligent future.

Frequently Asked Questions

It's completely normal to have questions when you're looking at a new piece of technology. If you're trying to figure out where AI inventory management software fits into your business, you're in the right place.

Let's walk through some of the most common questions we hear from business owners who are thinking about making this change.

Is This Only for Big Corporations?

That’s a myth we need to bust right away. While massive retailers were certainly the first to jump on board, the game has changed. Today's AI tools are far more accessible and affordable, with many designed from the ground up for small and medium-sized businesses.

Think about it this way: a small e-commerce shop and a national retail chain are both trying to solve the exact same puzzle—predicting what their customers want to buy. The scale is different, but the fundamental challenge is identical. Modern AI platforms are built to deliver results whether you're managing 200 SKUs or 200,000.

How Much Does It Typically Cost?

The price tag can swing quite a bit, but it’s no longer a million-dollar project reserved for the Fortune 500. Most software providers now use a subscription model, so you're not facing a massive upfront capital expense.

Pricing is usually tiered based on a few key metrics:

- The number of SKUs (products) you manage

- How many warehouses or locations you operate

- Your monthly order volume

This approach ensures you only pay for the capacity you actually use. When you're looking at the cost, remember to balance it against the savings. Studies have shown AI can reduce inventory holding costs by up to 30% by cutting down on overstock and preventing lost sales from stockouts. In many cases, the system pays for itself pretty quickly.

Expert Opinion: "The conversation shouldn't just be about the cost of the software, but the cost of not having it. Every dollar tied up in dead stock or lost to a stockout is a cost you're already paying. AI shifts that expense into an investment with a clear return."

How Long Does It Take to Get Started?

The timeline really depends on the complexity of your operations and, most importantly, the state of your data. A smaller online store with well-organized sales history could be up and running in just a few weeks. A larger company with multiple systems to connect might be looking at a few months.

The biggest variable is always data preparation. If your historical sales data is clean and accurate, the whole process moves much faster. Any good vendor will walk you through a clear implementation plan, helping with everything from data migration to getting your team trained up. The goal is always a smooth and efficient launch.

Ready to stop guessing and start making data-driven decisions? At YourAI2Day, we provide the latest news, tools, and insights to help businesses like yours understand and apply artificial intelligence. Explore our resources to stay ahead of the curve. Learn more at https://www.yourai2day.com.