Machine Learning in Manufacturing: Your Guide to Smarter Factories

Ever wished your factory equipment had a 'brain' to learn from experience? That’s the core idea behind machine learning in manufacturing. It’s a huge leap from just fixing things when they break to actively stopping problems before they even happen. Instead of just following pre-set instructions, your machines can use data to spot patterns, predict failures, and make smarter decisions all on their own. This is how a traditional factory transforms into a truly smart, efficient, and forward-thinking operation.

What Is Machine Learning in a Factory Setting?

Let's cut through the buzzwords and see what machine learning manufacturing actually looks like on the factory floor. Forget the sci-fi movies of robots taking over; the reality is much more practical and, honestly, more powerful. It’s all about teaching your equipment to think and adapt using the mountains of data it creates every single second.

Think of an experienced craftsman who knows just by the sound of a machine that something is slightly off. They’ve built that instinct over years. Machine learning gives your equipment that same kind of intuition, but it’s supercharged with an incredible amount of data.

From Reactive to Proactive Operations

For decades, manufacturing has been stuck in reactive mode. A machine breaks, the line stops, and a team scrambles to get it running again. This old way of doing things is expensive, causing unplanned downtime and frustrating delays. In fact, some reports show that companies using AI and ML can slash machine downtime by a massive 30% to 50%.

Machine learning completely flips this model on its head, creating a proactive strategy. You stop waiting for failures and start predicting them.

- Predictive Maintenance: Imagine sensors on a robotic arm detecting a tiny, almost imperceptible increase in vibration. An ML model, which has analyzed months of performance data, flags this as an early sign that a bearing will likely fail in the next 72 hours.

- Intelligent Decision-Making: The system doesn't just send an alert. It can automatically schedule maintenance during a planned break, order the right replacement part, and notify the correct technician.

This isn't just about preventing breakdowns. It’s a fundamental shift in how you manage your entire operation, moving you out of constant fire-fighting and into strategic, planned action.

"The core idea is simple: let the data do the talking. By listening to what your machines are telling you through data, you can anticipate needs, optimize processes, and avoid problems before they ever start."

The Brains Behind the Operation

So, how does a machine "learn"? It uses complex algorithms to comb through data from countless sources—production logs, sensor readings, and even images from quality control cameras. These algorithms are the engine of machine learning, allowing systems to get better over time without someone needing to manually write new code for every possible situation. For a deeper dive into the mechanics, you can explore our guide on how machine learning algorithms are explained.

This cycle of continuous learning is what makes machine learning manufacturing so powerful. It creates a factory that doesn’t just run; it evolves. It gets smarter and more efficient with every single thing it produces.

How Machine Learning Is Really Changing the Factory Floor

Now that we've got the big picture, let’s get down to the nitty-gritty. Understanding the concept of machine learning in manufacturing is one thing, but seeing it in action on the factory floor is where its true power really shines. This isn't about a massive, factory-wide overhaul overnight. It’s about making smart, targeted upgrades where intelligent systems can deliver the biggest bang for your buck.

We're going to dive into two of the most effective applications companies are putting to work right now: predictive maintenance and automated quality control. These aren't just futuristic ideas; they are practical tools delivering real results today, turning raw data into a genuine competitive edge.

Predicting Problems Before They Start with Predictive Maintenance

We’ve all been there. A critical machine on the assembly line suddenly grinds to a halt. Production stops, your team is left standing around, and every single minute of that downtime is burning a hole in your budget. This kind of reactive firefighting is an old and frustrating story in manufacturing. Predictive maintenance offers a much smarter way to work.

Instead of waiting for something to break, you use machine learning to see it coming. It starts with sensors on your equipment that constantly gather data on things like temperature, vibration, speed, and how much power a machine is drawing. All of this information is fed into an AI model that’s been trained on that specific machine's historical performance.

Over time, the model learns to spot the subtle digital "fingerprints" that are tell-tale signs of an impending failure. It might pick up on a tiny, almost imperceptible increase in vibration that signals a bearing is starting to wear out. The system can then flag this for your team days, or even weeks, in advance, letting you schedule the repair during planned downtime instead of in the middle of a critical production run.

Expert Insight: "Think of it like a doctor monitoring a patient's vital signs. Small changes can indicate a future health problem. Predictive maintenance does the same for your machines, catching issues before they become critical and costly emergencies."

In today's fast-paced manufacturing world, this proactive approach is a game-changer. Machine learning has become a core tool for predictive maintenance, slashing unscheduled downtime by as much as 41% for manufacturers that deploy AI-driven systems. This isn't a theoretical number; it comes from real-world factories where companies use ML to analyze sensor data from equipment like CNC machines and robotic arms. You can dig deeper into these kinds of smart manufacturing trends on ArcherPoint.

Achieving Superhuman Quality Control

Humans are amazing, but we get tired, distracted, and our eyes can't spot microscopic flaws. In manufacturing, even the tiniest defect can lead to a rejected product, wasted materials, or a disappointed customer. This is exactly where AI-powered quality control steps in, offering a level of precision that is simply beyond human capability.

The setup usually involves high-resolution cameras installed along the production line, capturing images of every single item that passes by. These images are analyzed in real-time by a machine learning model that has been trained on thousands of examples of both "perfect" and "defective" products.

The model learns to spot tiny imperfections with incredible accuracy—a minuscule crack, a slight variation in color, or a component that’s just a fraction of a millimeter out of place. When it detects a problem, it can instantly flag the item for removal or even signal the production line to adjust itself to stop the error from happening again.

A perfect real-world example is in the production of circuit boards. An AI vision system can inspect solder joints for tiny cracks or bridges that a human inspector could easily miss, ensuring every single board that leaves the factory is flawless. This not only boosts product quality but also dramatically reduces waste. In fact, some reports show that ML-powered vision systems can achieve defect detection rates of over 90%.

To help you see the practical value at a glance, here’s a quick summary of these high-value applications.

Top Machine Learning Use Cases in Manufacturing

| Use Case | How It Works | Key Business Benefit |

|---|---|---|

| Predictive Maintenance | Sensors collect equipment data (vibration, temperature) and an ML model predicts when parts will fail. | Reduces unplanned downtime, cuts emergency repair costs, and extends equipment lifespan. |

| Automated Quality Control | AI-powered cameras analyze products on the assembly line, identifying defects invisible to the human eye. | Improves product quality, lowers scrap rates, and increases customer satisfaction. |

Ultimately, these applications show that machine learning in manufacturing is less about futuristic robots and more about operational intelligence. It’s about using data to make smarter, more informed decisions that lead to big savings, better products, and a much more resilient business.

Your Toolkit for a First Machine Learning Project

So, you're ready to get your hands dirty with a machine learning manufacturing project? That’s fantastic. It’s more accessible than you might think, but a successful first run depends entirely on having the right foundation.

Think of it like building a custom piece of equipment. You can't start welding without the right blueprints and quality materials. For your first project, we'll focus on those two core components: the data you'll use and the tools you'll need to shape it. Getting these right from the get-go will save you countless headaches.

Gathering Your Core Ingredients: The Data

At its heart, machine learning is just a sophisticated way of learning from data. The better the data, the smarter the system becomes. The great news for manufacturers is that you're probably already sitting on a goldmine of information—the trick is knowing what to look for and how to polish it up.

You’ve definitely heard the old saying, "garbage in, garbage out." In machine learning, that’s not just a guideline; it's an iron law. If you feed a model messy, incomplete, or irrelevant data, the results will be unreliable at best and downright misleading at worst. Clean, well-organized data is non-negotiable.

Here are the most valuable types of data you can start with:

- Sensor Readings: Information from your equipment—like temperature, vibration, pressure, and power consumption—is the lifeblood of predictive maintenance.

- Production Logs: These records detail everything from cycle times and throughput rates to specific machine settings, giving you the operational context.

- Quality Control Reports: This is a big one. It includes everything from manual inspection notes to images of products, which are perfect for training models to spot defects automatically.

- Maintenance Records: Logs of past repairs, part replacements, and equipment failures are crucial for teaching a model what a "problem" looks like before it happens again.

Expert Tip for Beginners: Don't try to boil the ocean. Start with a single, well-defined problem, like predicting failures on one critical machine. Gather the relevant data for just that machine to keep your first project focused and manageable.

Choosing Your Tools and Models

Once you have your data, you need the right tools to turn it into actual insight. The tech landscape can look intimidating, but you don't need a team of data scientists to get started. Many modern platforms are built to be approachable.

Your choice of tools typically falls into two main camps:

- Cloud Platforms: Services like Amazon Web Services (AWS) and Microsoft Azure offer pre-built machine learning services. These are excellent starting points because they handle the heavy lifting, letting you upload your data and train a model with a more guided experience.

- Open-Source Libraries: For teams with more technical expertise, libraries like TensorFlow and PyTorch offer incredible flexibility. These are the building blocks that data scientists use to create custom models from scratch. To see how they stack up, you can learn more about different machine learning frameworks in our detailed guide.

Alongside the tools, you'll need to choose the right type of model for the job. Let’s break down two of the most common ones for manufacturing:

- Regression Models: Use these when you want to predict a number. For instance, a regression model could analyze sensor data to forecast the remaining useful life of a machine part in hours.

- Classification Models: Use these when you want to sort things into categories. A classic example is a quality control model that looks at a product image and classifies it as either "Pass" or "Fail."

Kicking off your first machine learning manufacturing project is a huge step. By focusing on high-quality data and selecting the right tools for your team's skill level, you’ll build a solid foundation for success and start seeing real-world benefits on your factory floor.

A Step-by-Step Guide to Implementing Machine Learning

Diving into a machine learning manufacturing project can feel like a huge commitment, but it really doesn't have to be. The trick is to follow a clear, phased approach that breaks a big idea down into a series of manageable tasks. Think of this as your practical roadmap from a concept to a real, working solution on your factory floor.

This guide is designed to be actionable, laying out the journey in five logical steps. By following this structure, you can sidestep common pitfalls and build momentum, proving the value of AI integration one confident step at a time. Let's get started.

Step 1: Start With a Clear Business Problem

Before you even think about algorithms or datasets, you need to nail down the business problem you're trying to solve. A vague goal like "improve efficiency" is a recipe for a project that goes nowhere. You need to get specific and make it measurable.

A great way to do this is to frame your problem with hard metrics. Instead of a fuzzy objective, aim for something like this:

- "Reduce unplanned downtime on Assembly Line 3 by 15% in the next six months."

- "Decrease the scrap rate for Part #X7B from 4% to under 1%."

- "Cut energy consumption from our CNC machines by 10% during peak hours."

Starting with a specific, quantifiable goal gives your project a clear finish line and makes it way easier to track your success.

Step 2: Gather and Prepare Your Data

Once you have a clear problem, you know exactly what data you need to hunt down. If your goal is to slash downtime on Assembly Line 3, you'll need its maintenance logs, sensor readings (vibration, temperature), and production schedules. The quality of this data is everything.

You'll have to clean it up and get it ready for analysis. This almost always involves:

- Handling Missing Values: Figuring out how to fill in the gaps where data wasn't recorded.

- Removing Outliers: Correcting or getting rid of obvious errors, like a temperature reading of 2,000 degrees on a machine that never exceeds 200.

- Standardizing Formats: Making sure all dates, times, and units of measurement are consistent across the board.

This step can eat up a lot of time, but it's arguably the most critical part of the whole process. Great data leads to reliable models; garbage in, garbage out.

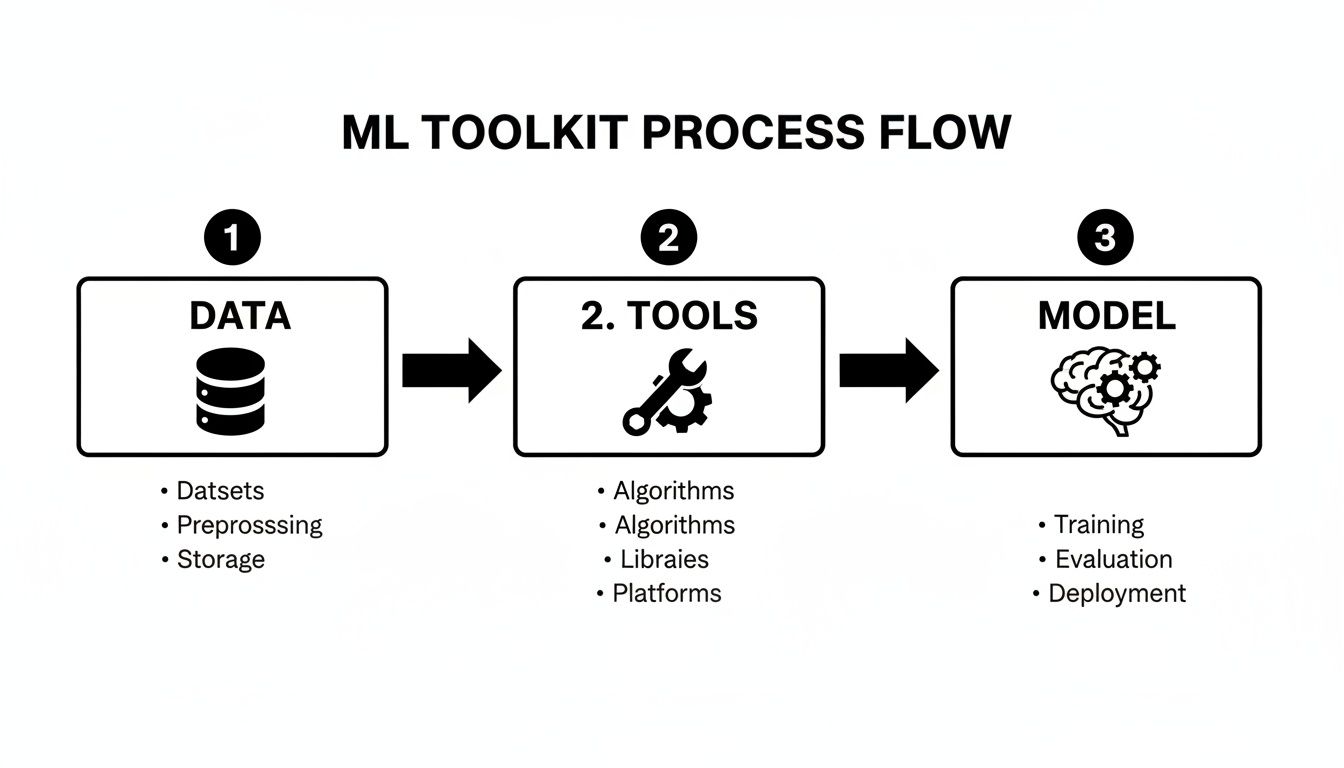

This simple flow chart shows how it all fits together. Success depends on a logical progression where clean data feeds the right tools, which in turn produce an intelligent model.

Step 3: Choose and Train a Simple Model

Now for the fun part: building the "brain" of your solution. For a first project, simplicity is your best friend. Don't get distracted by the most complex, state-of-the-art algorithm. Start with a proven, straightforward model that’s a good fit for your specific problem.

For instance, if you’re trying to predict equipment failure (a number, like hours until the next breakdown), a regression model is a great choice. If you're trying to identify product defects (a category, like "pass" or "fail"), a classification model is what you need. You'll feed your squeaky-clean data into the model and let it "learn" the hidden patterns.

Expert Opinion: "The biggest mistake beginners make is overcomplicating things. Start with the smallest, simplest project that can deliver real value. A successful pilot builds trust and momentum, making it much easier to get buy-in for more ambitious projects down the road."

Step 4: Test and Validate in a Pilot Project

Once your model is trained, it's time to see how it performs in the real world—but on a small, controlled scale. A pilot project is a low-risk way to kick the tires. For example, you could run your predictive maintenance model on just a single machine instead of the entire factory.

During this phase, you'll compare the model's predictions to what actually happens. Did it correctly forecast a failure? Did it flag a defective part that human inspectors missed? This is your chance to fine-tune the model and prove its business value with hard data before committing to a full-scale rollout.

Step 5: Scale Your Solution

With a successful pilot under your belt, you now have the proof you need to go big. This involves rolling out the model across more machines, production lines, or even entire facilities. At this point, the project becomes less about data science and more about implementation and change management.

Scaling up means weaving the model's insights into your team's daily workflows. This could involve setting up automated alerts, creating dashboards for operators to monitor, and training staff to trust and act on what the model tells them. Once you've mastered this, you'll need to think about the long-term care of your system. To go further, check out our complete guide on machine learning model deployment for best practices.

Real-World Wins From Machine Learning in Action

It’s one thing to talk about models and algorithms, but it’s another to see them deliver real, measurable results on the factory floor. So, let's shift from theory to reality and look at how machine learning manufacturing is making a tangible impact.

These aren't just stories from massive tech giants with bottomless budgets. They’re practical examples of how targeted AI solutions are solving everyday manufacturing problems. The goal here is to make the potential of machine learning feel concrete and, most importantly, achievable for your own operation.

Boosting Solar Panel Quality with Computer Vision

A solar panel manufacturer was wrestling with a classic but costly problem: tiny, almost invisible micro-cracks appearing during production. These defects were incredibly difficult for human inspectors to catch consistently, which led to product failures down the line, unhappy customers, and expensive warranty claims.

To fix this, the company installed high-resolution cameras over its assembly line and trained a computer vision model. This AI learned to spot the subtle visual signatures of micro-cracks by analyzing thousands of images of both perfect and flawed panels. In short, it became an expert inspector that never got tired or distracted.

The impact was immediate. The new AI system could identify defects with incredible speed and precision, flagging flawed panels for removal in real time. This single change drastically cut their scrap rates, reduced warranty claims, and boosted overall product quality.

Quality control in manufacturing has been supercharged by machine learning-powered computer vision, achieving defect detection rates over 90% in real applications like solar panel production. A solar panel manufacturer, for example, boosted its accuracy dramatically, cutting scrap rates and warranty claims that previously eroded profits. You can learn more about how machine learning is improving manufacturing on Tech-Stack.com.

Averting Disaster with Predictive Maintenance

Now, picture a mid-sized company that relies heavily on a critical piece of CNC machinery. Unplanned breakdowns were a constant headache, halting production for hours—sometimes days—at a time. The emergency repair costs were steep, but the lost production time was what really hurt the bottom line.

They decided to get ahead of the problem with predictive maintenance. The team fitted the machine with sensors to monitor key indicators like vibration, temperature, and power usage. All this data was then streamed to a machine learning model that learned the machine’s normal operating behavior.

After a few weeks of learning, the model started flagging subtle anomalies that were invisible to the human eye but were clear precursors to failure. In one case, it detected a slight increase in vibration and alerted the team that a specific motor bearing was likely to fail within the next 48 hours. The maintenance crew scheduled the repair during a planned overnight shutdown, swapping out the part before it could cause a catastrophic failure.

This proactive fix saved the company thousands in emergency costs and prevented an estimated 12 hours of lost production.

These stories show that machine learning manufacturing isn't always about a massive, factory-wide overhaul. Often, it's about finding a specific, painful problem and applying a smart, focused solution. Whether it's perfecting product quality or preventing costly downtime, AI offers a practical path to a more efficient and resilient operation.

Measuring Success and Avoiding Common Pitfalls

So, you’ve launched a machine learning project on your factory floor. That’s a huge step. But how do you actually know if it's working? Without the right way to measure success, even the most sophisticated AI is just a shiny, expensive toy. Figuring out what to track and what to watch out for is what separates a successful initiative from a pilot project that gets quietly shelved.

This is the moment you have to connect the dots between your AI solution and the business problem you were trying to solve in the first place. This isn't about bragging about algorithms; it's about making a real impact on the numbers that drive your business. Let's dig into how you can track your return on investment (ROI) and steer clear of the classic mistakes that can sink these projects before they even get going.

Key Metrics to Track Your Progress

To really show the value of your work, you need to speak the language of the business. Abstract benefits just don't cut it. You have to focus on tangible Key Performance Indicators (KPIs) that directly tie back to improvements on the shop floor. We've seen firsthand how companies that get this right achieve some impressive results, like cutting machine downtime by anywhere from 30% to 50%.

Here are the core metrics you should have on your dashboard:

- Overall Equipment Effectiveness (OEE): This is the classic, all-in-one metric for manufacturing productivity. If your OEE score is climbing, it’s a strong signal that your ML model is making a positive difference in availability, performance, or quality.

- Scrap Rate Reduction: For any project focused on quality control, this is your bottom line. Tracking the reduction in wasted material gives you a crystal-clear, easy-to-calculate ROI.

- Decreased Downtime: If you’re doing predictive maintenance, this is the big one. You need to log the hours of unplanned downtime before you started and compare it to the hours after your model went live. The difference is your impact.

- Maintenance Costs: A good ML model should help you move away from expensive, reactive repairs toward planned, much cheaper maintenance. Keep a close eye on your total spend for parts and labor.

Navigating the Most Common Hurdles

Look, any new technology has a learning curve. Knowing the common pitfalls of applying machine learning in manufacturing is the best way to avoid them. Here’s a look at what trips up most teams and how you can sidestep these issues.

Expert Opinion: “The single biggest piece of advice I can give is to start small. Don’t try to boil the ocean. Pick one specific, high-impact problem, solve it with a simple model, and prove its value. A successful small win builds the confidence and buy-in you need to tackle bigger challenges.”

Let's break down the top three challenges and how to handle them.

-

Poor Data Quality: This is, without a doubt, the number one project killer. If the historical data you're feeding the model is messy, incomplete, or just plain wrong, its predictions will be completely worthless. Garbage in, garbage out.

- The Fix: You have to invest serious time in data cleaning before you even think about model training. A good way to start is by focusing on a single, trusted data source from one machine. This keeps the initial task from feeling overwhelming.

-

Lack of Specific Skills: Too many companies jump in without someone on the team who truly understands both the manufacturing process and the fundamentals of data analysis.

- The Fix: You don't need to hire a whole team of data scientists to get started. Find a tech-savvy engineer who knows your operations inside and out, and get them trained on a user-friendly cloud AI platform. Their process knowledge combined with a powerful tool is often the perfect combination for a first win.

-

Unrealistic Expectations: If you’re expecting a perfect, all-knowing AI on day one, you’re setting yourself up for disappointment. Machine learning models aren't magic; they need time to learn and require constant fine-tuning.

- The Fix: Treat your first project as a pilot or a proof of concept. Set realistic, incremental goals. Aim to improve failure prediction accuracy by 10%, not 100%. Celebrate those small victories—they build the momentum you need for the long haul.

Frequently Asked Questions About ML in Manufacturing

It’s completely normal to have a lot of questions when you first start exploring machine learning for your factory. If you're a business owner or a plant manager trying to get your bearings, you're in good company. We’ve pulled together answers to some of the most common questions we hear from people just like you.

Do I Need a Team of Data Scientists to Start?

Not always, and definitely not for your first pilot project. While a full data science team is crucial for tackling massive, complex initiatives, you can get started without one.

Today's cloud platforms from AWS, Google Cloud, and Microsoft Azure offer incredibly powerful "low-code" or "no-code" machine learning tools. These services let you upload your own data and train a predictive model through a simple visual interface, no heavy coding required. For a focused first project, like predicting when a single, critical machine needs maintenance, a sharp engineer who knows your operations inside and out can often use these tools to build a proof-of-concept and show real ROI.

How Much Data Do I Need to Get Started?

This is the classic "it depends" question, but I can give you some solid guideposts. There's no single magic number, because the amount of data you need is tied directly to the complexity of the problem you're trying to solve. For most initial projects, a few thousand historical data points is a good target to give the model enough examples to find meaningful patterns.

Let's make that more concrete:

- Predictive Maintenance: If you have a year's worth of sensor data (think temperature, vibration, pressure) and maintenance logs for one machine, that’s a fantastic starting point.

- Quality Control: To train a computer vision model that spots defects, you'll likely need several thousand images of both "good" parts and various types of "bad" parts.

Remember, quality trumps quantity. The best first step is to pick one clear business problem and then go looking for the data you already have. You might be surprised by what's already being collected.

The Biggest Mistake Companies Make With AI

The most common pitfall we see is treating AI as a technology project instead of a business solution. Success isn't about having the coolest algorithm; it's about starting with a specific, measurable goal like "reduce scrap by 15%" or "cut unplanned downtime by 20%." Always lead with the question, "What business problem are we solving?" This focus is what ensures your machine learning project actually delivers value to the bottom line.

At YourAI2Day, our mission is to give you the real-world insights and resources you need to understand and apply artificial intelligence. To learn more, visit us at yourai2day.com.